Original article: Electronicdesign.com

Pliable zinc-oxide/aramid-fiber batteries can be distributed structural elements in small robots, allowing for increased battery volume along with decreased weight, both resulting in longer runtimes. One of the many factors that affects the run time of untethered robots of all sizes is their power/weight ratio. This dilemma is aggravated by the fact that the standard practice of placing the batteries in their own distinct location limited their allowed volume.

In contrast, for most living organisms, motive energy is distributed and stored throughout the body (think muscles); macroscale biological systems don’t have a distinct organ that’s analogous to a discrete battery. Replacing traditional standalone batteries in robotic devices with conformal, multifunctional, biomorphic cells can, in principle, extend their operational time while reducing weight.

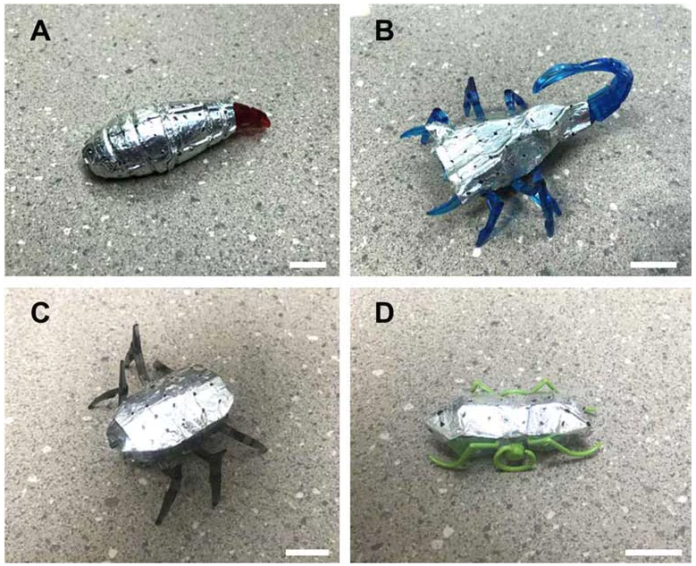

Now, a research team based at the University of Michigan, Ann Arbor, MI, United States, is addressing the issue by developing tiny batteries using composites based on aramid nanofibers with a cartilage-like nanoscale structure to combine mechanical and ion transport (battery) properties. The ion-conducting membranes from these composites enable pliable, flexible, zinc-air batteries that can also act as protective covers and support members in robots including soft and flexible miniaturized versions.

The project began with work on the battery materials, chemistry, and charging/discharging cycles using zinc-air battery technology. Nicholas Kotov, the ‘Joseph B. and Florence V. Cejka’ Professor of Engineering who led the research, acknowledged that “no other structural battery reported is comparable, in terms of energy density, to today’s state-of-the-art advanced lithium batteries.”

Another downside of zinc-air batteries is that they maintain their high capacity for about 100 cycles, rather than the 500 or more that we expect from the lithium-ion batteries in our smartphones. The primary reason for that is the zinc metal forms spikes that eventually pierce the membrane between the electrodes.

Zinc Upside

So why use zinc? The strong yet pliable aramid-nanofiber matrix between the electrodes is the key to the relatively long cycle life for a zinc battery, while the inexpensive and recyclable materials make the batteries easy to replace compared to lithium batteries. Using the zinc-air approach with ion-conducting membranes based on these aramid nanofiber composites (the same carbon-based fibers as found in Kevlar vests) and a water-based polymer gel enable development of pliable batteries that can then be used on the surface of the robotic device.

Further, the gel and aramid nanofibers will not catch fire if the battery is damaged, unlike the flammable electrolyte in lithium-ion batteries. The battery materials are abundant and largely nontoxic materials, and the battery is more environmentally friendly than those currently in use. The new battery works by passing hydroxide ions between a zinc electrode and the air side through an electrolyte membrane. That membrane is partly a network of these aramid nanofibers and the gel, which helps transport the hydroxide ions between the electrodes […]

Full article: Electronicdesign.com