SIGMA Lithium Resources Corporation, São Paulo, Brazil, (TSX-V: SGMA) (OTC- QB: SGMLF) has announced exceptional results of metallurgical tests (“Met Tests”) performed to evaluate, among other parameters, the recovery of lithium from the Barreiro deposit (Barreiro, Araxá, Minas Gerais, Brazil) proposed to be developed in Phase 2 of the Company’s Grota do Cirilo Project (the “Project”). The Met Tests included a heavy liquid separation (“HLS”) test to evaluate the extent to which a gravity-based separation process, or dense media separation (“DMS”), could successfully recover the lithium from the spodumene ore.

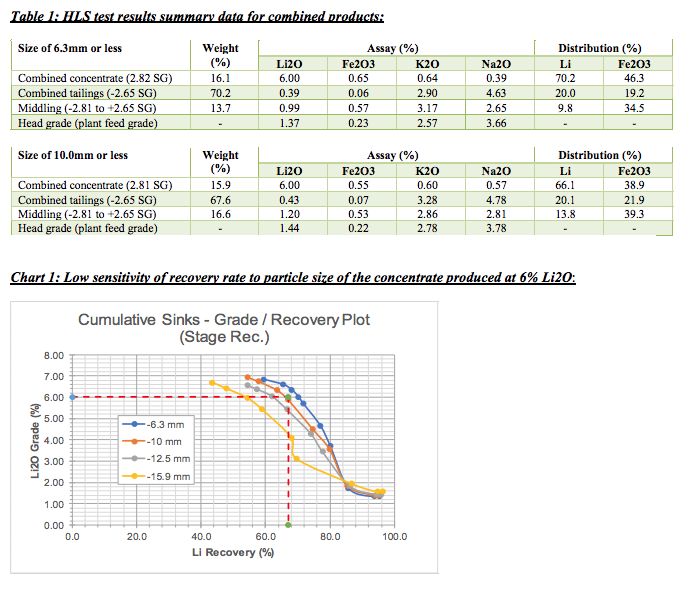

HLS test work done on ore sizes of 6.3mm and 10mm achieved excellent lithium recoveries of 70.2 % and 66.1%, respectively, producing a 6% Li2O battery-grade spodumene concentrate within the highest levels of specifications demanded by the chemical lithium market without the use of flotation or hazardous chemical reagents, such as sulphuric acid, in the concentration process. This is consistent with Sigma’s intention to continue to process its lithium ore in a “green” environmentally-friendly and sustainable manner.

The Met Tests results will be used to support the study currently underway to update the technical report titled “Grota do Cirilo Lithium Project, Araçuaí and Itinga Regions, Minas Gerais, Brazil, National Instrument 43-101 Technical Report on Feasibility Study Final Report”, dated October 18, 2019 (the “Feasibility Study Report”). As detailed in its news release of December 7, 2020, the Company commissioned SGS Canada Inc. to update the Feasibility Study Report to include the mining and processing of ore from the Barreiro deposit with the objective of doubling the Company’s planned production capacity of high-purity “green & sustainable” 6% Li2O batterygrade spodumene concentrate to 440,000tpy in Phase 2 of the Project. The Company is in pre-construction phase (including the EPC and “contract-readiness” of core construction suppliers) of its larger-scale lithium concentration commercial production plant (the “Production Plant”).

The key conclusions of the Met Tests for the update of the Feasibility Study Report are as follows:

The results indicate that the ore from the Barreiro (Phase 2) deposit can be processed in combination with ore from the Xuxa (Phase 1) deposit in the same Production Plant, as designed in the Feasibility Study Report, without requiring major flowsheet modifications, and thus with low additional capex needs

The results provide validation of the potential for gains of scale at the Production Plant resulting from its doubling of capacity by adding a second DMS production line to process the ore from the Barreiro deposit

The results support the potential for substantial economies of scale for the Project as a whole resulting from the addition of production from the Barreiro deposit.

Calvyn Gardner, Chief Executive Officer and Co-Chairman of Sigma’s Board of Directors said: “The doubling of planned capacity with low additional capex indicated by the Met Tests has the potential to significantly transform Sigma, enhancing its economies of scale. We are very pleased to have successfully concluded this crucial step with SGS Canada Inc., as part of the workstreams involved in updating the Feasibility Study Report with the Barreiro (Phase 2) deposit, which would be fully integrated into the production complex for the Xuxa (Phase 1) deposit, currently in pre-construction. The Feasibility Study Report has 20.5 million tonnes of measured and indicated mineral resources (10.3MT measured and 10.2MT indicated) in the Barreiro deposit from which to support an estimation of mineral reserves currently in progress by SGS Canada Inc.

”The Met Tests were completed from a sample of 1250kg of drill core representative of the Barreiro deposit, which is one of the nine deposits on the Company’s properties and the second being developed at the Project. The HLS tests were conducted on the basis of a three-stage DMS processing production line (processing coarse, fine and ultrafine materials), with a flowsheet similar to the DMS production line for the Xuxa deposit designed for the Production Plant included in the Feasibility Study Report. HLS is only a perfect separation based on the minerals’ specific gravity (“SG”). Thus, to evaluate DMS performance and separation efficiency in the real industrial environment, DMS testwork will be conducted on the same sample in the upcoming months.

HLS test highlights:

For 6.3mm and 10mm coarse size fractions, excellent lithium recoveries were achieved of 70.2 % and 66.1%, respectively, through gravity separation, without the use of flotation or hazardous chemical reagents, such as sulphuric acid, in the lithium concentration process. This is consistent with Sigma’s intention to continue to process its lithium ore in a “green” environmentally-friendly and sustainable manner, as mentioned above.

The head grades of 1.37% and 1.44% Li2O for the samples selected for the 6.3mm and 10mm coarse size fractions, respectively, are close to the 1.42% average grade for measured and indicated mineral resources currently defined for the Barreiro deposit.

Results are very similar to those for the Xuxa deposit in that a high purity concentrate was produced with very low levels of alkalines (sodium oxide and potassium oxide) and iron oxide, which were all well below 1%.

The optimum feed size for the DMS ought to be between 6.3mm and 10.0mm, as shown in Chart 1 below, so as to maximize recovery while minimizing fines production, with feeds outside this range achieving sub-optimal results, as indicated by the various curves plotted in the chart for each particle size showing the Li2O grades versus the recoveries achieved.

About SIGMA Lithium Resources

Sigma is a Canadian company that has been producing environmentally sustainable battery-grade lithium concentrate on a pilot scale since 2018 and shipping high-purity “green & sustainable” 6% Li2O battery-grade lithium concentrate samples to some of the leading global cathode and battery producers of electric vehicles. The company is in pre-construction (including the EPC and “contract-readiness” of core construction suppliers) of its larger-scale lithium concentration commercial production plant. Based on the Feasibility Study Report, it will contemplate a capacity to produce at the rate of 220,000 tonnes annually of battery-grade “green” lithium concentrate and Sigma will be amongst the lowest-cost producers of lithium concentrate globally.

The Feasibility Study Report is being updated to include the development of the Project’s second deposit, contemplating production at the rate of 440,000 tonnes per annum (Phase 2 of the Project). To secure a leading position supplying the clean mobility and green energy storage value chain, Sigma has adhered to the highest standards of environmental practices in line with its core values and mission since starting activities in 2012. Sigma’s production process is powered by hydroelectricity and the Company utilizes state-ofthe-art dry-stacking tailings management and water-recycling techniques in its beneficiation process. Its corporate mission is to execute its strategy while embracing strict ESG principles. Sigma’s shareholders include some of the largest ESG-focused institutional investors in the world.