As batteries become increasingly important in a world filled with portable electronics, Montana State University (MSU), United States, is poised to push the boundaries of energy storage technology as part of a $10 million effort involving universities, national labs and industry partners, Montana.edu reports.

MSU was recently awarded more than $3.5 million from the Army Research Lab to develop a new generation of batteries that can hold more power and charge faster while also being safer and more resilient to extreme environments. The project is being led by University of Maryland and includes Stony Brook University, the University of Texas at Austin, Argonne and Brookhaven national laboratories and several private companies.

“MSU has some unique capabilities that we’ve developed over the past couple decades of researching fuel cells,” which are similar to batteries in many ways, said MSU Energy Research Institute Director Lee Spangler, who is leading the MSU portion of the project. “It’s exciting to be applying that expertise to batteries, and this funding is really going to accelerate our research in this area.”

Recent advances in lithium-ion batteries have enabled smaller laptops, longer-range electric cars and much more, but the batteries face challenges in the rigorous conditions of military field operations, according to Spangler. Soldiers carry an average of 10 pounds of batteries and have limited time for charging them, and traditional lithium-ion batteries can catch fire if damaged or overheated. Improved batteries that could excel in a military setting would also benefit a range of consumer products, Spangler said.

The MSU research team will focus on developing and testing lithium-ion batteries that use a specialized ceramic material in place of the plastic membrane and liquid electrolyte that are prone to damage and fire. The solid material would be more durable and, therefore, safer and may also have performance advantages such as faster charging time, according to Spangler.

“It turns out these novel ceramic structures that we developed for fuel cells appear equally advantageous for solid-state batteries,” said project researcher Stephen Sofie, professor in the Department of Mechanical and Industrial Engineering in MSU’s Norm Asbjornson College of Engineering. Fuel cells operate similarly to batteries to convert chemical inputs into electricity rather than storing and releasing it. “The ceramics will never catch fire and create a safety hazard and are capable of better performance than lithium batteries filled with flammable liquid.”

To make the ceramic material, Sofie will use a method called freeze-casting that he developed at NASA and has since refined over years of fuel cell research at MSU. A slurry of ceramic particles and water is precisely poured onto a cold surface to form ice crystals that produce the desired structure, then freeze-dried to make a thin, porous membrane.

“We think there’s so much promise for these ceramic battery materials if we can figure out how to package them to make robust, high performance battery cells,” Sofie said.

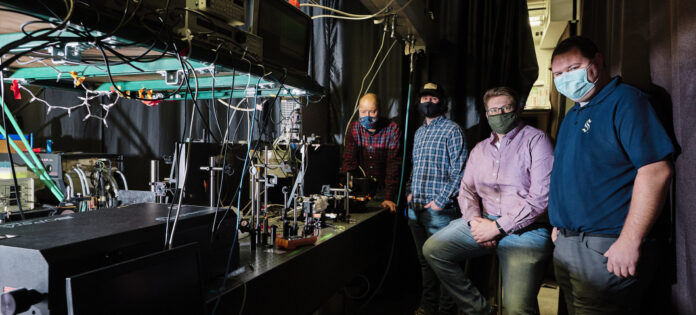

Rob Walker, professor in the Department of Chemistry and Biochemistry in MSU’s College of Letters and Science, is also applying expertise acquired over nearly two decades of researching high-temperature fuel cells. Walker and his group will use specialized equipment to study the stability of the new ceramics and the effects of impurities on their performance. Using optical spectroscopy, the researchers will be able to examine changes in materials at temperatures exceeding 1,800 degrees Fahrenheit. “There are very few other places in the world that can perform these types of measurements,” he said. “We’ll be able to know exactly how the battery material changes and correlate that with battery performance.”

Nick Stadie, assistant professor in the chemistry and biochemistry department and an expert in energy storage, will focus on developing graphite- and silicon-based materials for the electrodes that release and absorb energy during battery operation. Professor Steven Shaw in the Department of Electrical and Computer Engineering will design and build testing equipment for analyzing the performance of small versions of the new batteries to understand how they could optimally charge and provide power once scaled up. Hongwei Gao, associate professor in the electrical and computer engineering department, will develop protocols and devices to improve charging speed while reducing battery degradation and overheating.

Working with the other project partners on a range of testing and analysis, the MSU team’s ultimate goal is to create a new battery technology that could one day be manufactured for wide use, according to Spangler.

Walker called the project “a tremendous opportunity” for the MSU research community, including students and young researchers. The $3 million contract will support 11 graduate students and six postdoctoral or similar research positions. “Personnel working on this project will be well positioned to become leaders in the rapidly growing field of energy storage and conversion,” he said.

According to Sofie, the project couldn’t come at a better time, as MSU has started to leverage its fuel cell experience into research in the up-and-coming battery field. “We think this project will launch MSU into being a leader in solid-state battery research,” he said.