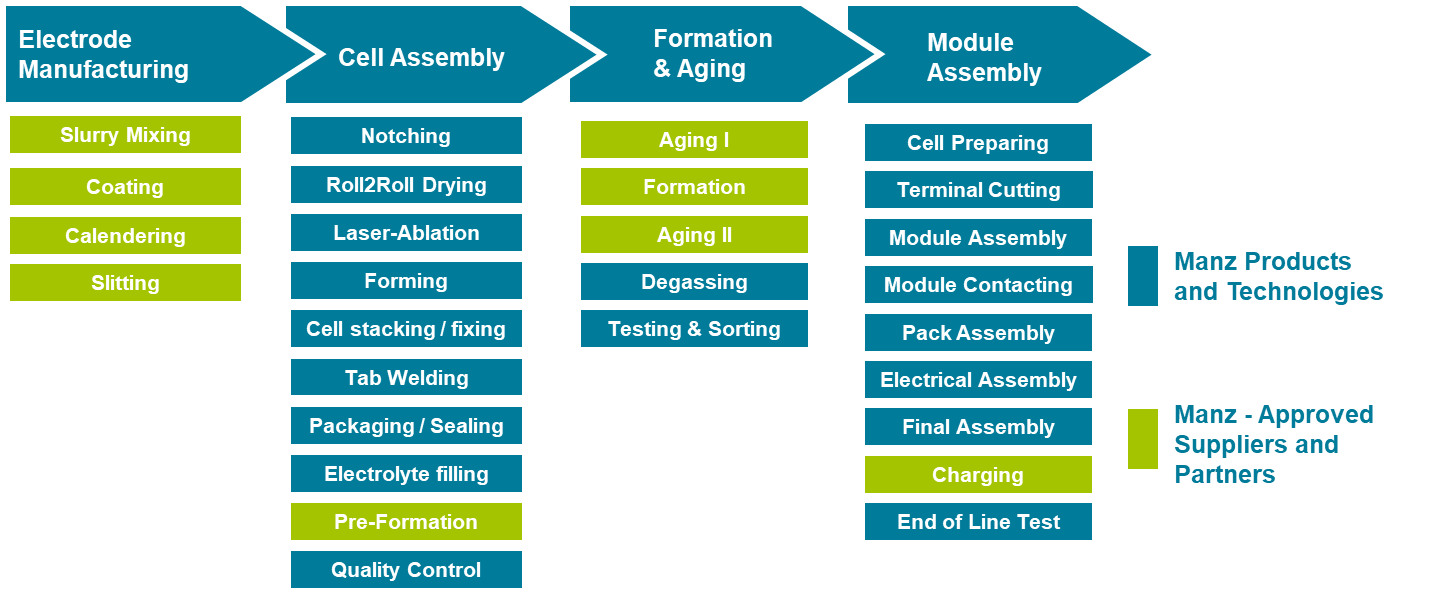

Manz AG, Reutlingen, Germany, a global high-tech machine manufacturer with a comprehensive technology portfolio, is experiencing a rapidly growing demand for production systems for high-performance and efficient battery systems in the energy storage sector. With electromobility as a driver and at the same time increasing cost pressure in production, the company’s solution competence is in great demand across all industries. In combination with strong partners around the world, Manz, as a provider of turnkey production lines, provides the complete production process for the manufacture of lithium-ion battery cells and modules. The Manz portfolio covers the entire spectrum of production solutions from single machines to systems for pilot, small and large series production to turnkey solutions – all from a single source.

As a pioneer for innovative products in rapidly growing markets, Manz supports its customers as the ideal partner in the planning and implementation of production solutions with its many years of expertise: reliable, experienced, and focused on customer needs and costs. For customers, the total view on the production line creates significant competitive advantages in terms of effectiveness, performance and safety of their battery cells and modules. The primary goal is quality, stability and cost efficiency by reducing frictional losses with a high integration factor. Manz’s customers come from the automotive, stationary energy storage and consumer electronics industries – including global companies and brands.

Innovation as a guarantee for added value

With over 30 years of experience, Manz is an innovation driver in the manufacturing of lithium-Ion battery cells and modules as well as capacitors and offers proven and tested technologies at competitive prices under the claim “passion for efficiency”. The extensive process experience enables processes to be developed in the shortest possible time from the idea to series production, with close interlinking of the technologies for every process step such as coating, forming, lamination, welding and winding. More than 500 engineers, a large number of patents and numerous collaborations with renowned research institutes stand for Manz’s innovative strength, based on European standards.

“We support our customers from the first feasibility study to prototypes of machines that manufacture small quantities in a semi-automated manner under real production conditions, to individual machines or complete production lines – and are therefore a trustworthy development partner for future markets. In addition, with fully integrated turnkey production solutions, we map the entire value chain, right up to our own new software platform for monitoring production systems, the SmartPRODUCTIONKIT”, emphasizes Andreas Schaal, Head of Sales Energy Storage at the high-tech machine manufacturer Manz.

Maximum flexibility in production planning

As a system supplier for the production of lithium-ion battery cells and modules, Manz offers flexible, scalable and modular machine and system concepts with a high integration factor. Production lines are freely configurable and can be used both as pilot lines and in automated mass production. Manz is the only European machine manufacturer to cover all essential production technologies for all lithium-ion cell concepts. For customers, this means maximum flexibility and cost efficiency, with high investment security at the same time – even in mass production.

International presence for short development and delivery times

The company helps key technologies to breakthrough through its innovative strength. The global sales and service network as well as R&D and production locations in Europe and Asia ensure customer proximity and enable short development and delivery times. Complemented by its own subsidiaries in all relevant markets and strategic partnerships in important markets such as China, Manz is also active internationally as a turnkey supplier with its range of products in the energy storage sector.

Find out more on: