Altech Chemicals Limited, Subiaco, Australia, (ASX: ATC) (FRA: A3Y) has announced the successful application of its alumina nano layer coating technology to the coating of silicon particles, typical of those used in anode applications within lithium-ion batteries.

The successful application of Altech’s technology to coat silicon particles follows its 22 December 2020, announcement where the Company provided details of its success in the alumina nano layer coating of graphite particles typical of those used in a lithium-ion battery.

Extending the application of the technology to the coating of silicon particles is a significant breakthrough for Altech, especially in the context of a recent public statement of US electric vehicle manufacturer Tesla, that its aim is to increase the amount of silicon in its batteries to achieve step-change improvements in energy density and battery life. Silicon has a significant advantage over graphite for use in lithium-ion battery anodes in that it has ten times the theoretical energy capacity compared to graphite. However, limitations for silicon use in battery anodes have included particle volume expansion of up to 300% when energised, and a large “first cycle lithium loss”. Industry believes that the encapsulation of silicon particles via the application of a nano layer of alumina can resolve these issues and be a “game changer” which would pave the way for increased lithium-ion battery energy density, lifespan and reduced first cycle lithium loss.

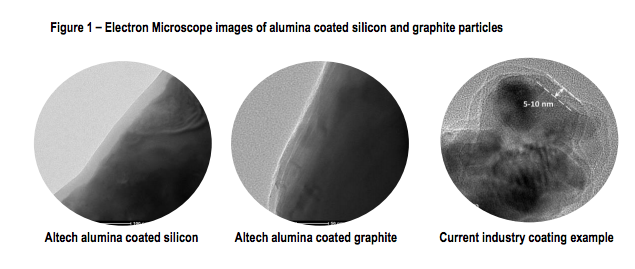

To test its fine particle alumina coating technology, Altech used silicon samples that were provided by its collaboration partner Silicio Ferrosolar, a subsidiary of the Ferroglobe Group. The nano coating of alumina onto lithium-ion battery grade anode materials such as silicon, has been very difficult for industry to achieve. In the case of silicon particles they have unique characteristics that required Altech’s coating technology to be adjusted in order to achieve the required outcome. As seen under the microscope (Figure 1), Altech was able to deposit a uniform and consistent layer of alumina on the outer edge of the silicon particle, encapsulating the particle, this is Altech’s alumina coating technology.

Altech’s general manager operations and chief scientist, Dr Jingyuan Liu said that verification of Altech’s coating technology on silicon particles is very exciting for the Company. “We are very encouraged by the excellent coating results achieved from the application of our technology, it has the potential to significantly increase the use of silicon in lithium-ion battery anode and consequently the potential to increase battery energy density, overall performance and longevity. The next step is to further optimise the coating process”, he said.

About Altech Chemicals

Altech Chemicals Limited is aiming to become one of the world’s leading suppliers of 99.99% (4N) high purity alumina (Al2O3) through the construction and operation of a 4,500tpa high purity alumina (HPA) processing plant at Johor, Malaysia. Feedstock for the plant will be sourced from the Company’s 100%-owned kaolin deposit at Meckering, Western Australia and shipped to Malaysia.

HPA is a high-value, high margin and highly demanded product as it is the critical ingredient required for the production of synthetic sapphire. Synthetic sapphire is used in the manufacture of substrates for LED lights, semiconductor wafers used in the electronics industry, and scratch-resistant sapphire glass used for wristwatch faces, optical windows and smartphone components. Increasingly HPA is used by lithium-ion battery manufacturers as the coating on the battery’s separator, which improves performance, longevity and safety of the battery. With global HPA demand approximately 19,000t (2018), it is estimated that this demand will grow at a compound annual growth rate (CAGR) of 30% (2018-2028); by 2028 HPA market demand is forecast to be approximately 272,000t, driven by the increasing adoption of LEDs worldwide as well as the demand for HPA by lithium-ion battery manufacturers to serve the surging electric vehicle market.

German engineering firm SMS group GmbH (SMS) is the appointed EPC contractor for construction of Altech’s Malaysian HPA plant. SMS has provided a USD280 million fixed price turnkey contract and has proposed clear and concise guarantees to Altech for pl ant throughput and completion. Altech has executed an off-take sales arrangement with Mitsubishi Corporation’s Australian subsidiary, Mitsubishi Australia Ltd covering the first 10-years of HPA production from the plant.

Conservative (bank case) cash flow modelling of the project shows a pre-tax net present value of USD505.6million at a discount rate of 7.5%. The Project generates annual average net free cash of ~USD76million at full production (allowing for sustaining capital and before debt servicing and tax), with an attractive margin on HPA sales of ~63%. (Refer to ASX Announcement “Positive Final Investment Decision Study for 4,500TPA HPA project” dated 23 October 2017 for complete details. The Company confirms that as at the date of this announcement there are no material changes to the key assumptions adopted in the study).

The Company has been successful in securing senior project debt finance of USD190 million from German government owned KfW IPEX-Bank as senior lender. Altech has also mandated Macquarie Bank as the preferred mezzanine lender for the project. The indicative and non-binding mezzanine debt term sheet (progressing through due diligence) is for a facility amount of up to USD90 million. To maintain project momentum during the period leading up to financial close, Altech has raised ~A$39 million in the last 24 months to fund the commencement of Stage 1 and 2 of the plant’s construction; Stage 1 construction commenced in February 2019 with Stage 2 early works completed at the end of June 2020.