Innovative silicon solutions provider HPQ Silicon Resources Inc., Montréal, Canada, (TSX-V: HPQ; FWB: UGE; Other OTC: URAGF), through its wholly-owned subsidiary, HPQ Nano Silicon Powders Inc., (“HPQ NANO”),has updated shareholders on milestones achieved during ongoing Gen1 PUREVAP™ Nano Silicon Reactor (“NSiR”) commissioning tests conducted by technology provider PyroGenesis Canada Inc. (TSX: PYR).

“With the Gen1 PUREVAP™ NSiR operational and exceeding expectations from the start, HPQ NANO is uniquely positioned to be at the forefront of low-cost manufacturing of Nano Silicon for batteries and other applications, as we continue working on scaling up the capabilities of our PUREVAP™ NSiR process,” said Bernard Tourillon, President and CEO HPQ Silicon.

PUREVAP™ NSiR LOW-COST PROCESS: FIRST RESULTS ENCOURAGING, MORE TESTING TO FOLLOW

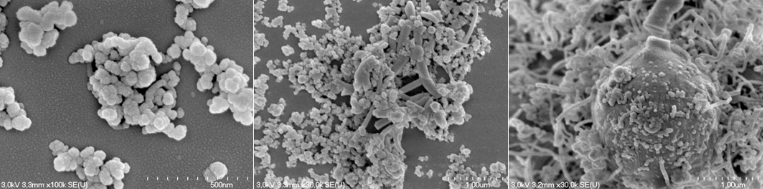

The material produced, under the less than optimum operating conditions of the first commissioning tests, was analyzed by scanning electron microscope (SEM) imaging combined with X-ray diffraction (XRD) and yielded the following information:

- Gen1 NSiR system performance exceeded design and modelling expectations:

– Successfully produced sub 100 nm silicon-based spherical nanopowders & nanowires.

– Computer models suggested that the size limit of the material produced would be between 100 nm and 200 nm.

- SEM-XRD analysis indicates that the < 100 nm Si base spherical nanopowders & nanowires material could be used as anode material for Li-ion batteries, combined with graphite or not.

- Samples from these commissioning tests have been sent to Professor Lionel ROUÉ of the Centre Énergie Matériaux Télécommunications (EMT) for electrochemical evaluation.

- Using results from data collected during these preliminary tests, PyroGenesis technical team has improved the design of the system and the operational parameters of the reactor.

– It will be possible to provide further inputs and controls on the process to customize the composition and size of the spherical nanopowders and nanowires.

- The Gen1 NSiR is now ready to commence further testing of Silicon nanomaterials under new conditions, with a goal of producing larger size Silicon (Si) nanopowders and nanowires.

A METHODICAL APPROACH TO THE COMMERCIAL DEVELOPMENT OF OUR DISRUPTIVE TECHNOLOGY

Despite massive investment in Silicon material for batteries, current manufacturing processes are simply not scalable or commercially viable. The PUREVAP™ NSiR represents a game-changing leap forward in resolving the issues of commercial viability and scalability, and with the Gen1 NSiR now operational, HPQ NANO is uniquely well-positioned to offer industry participants a wide spectrum of products for testing.

The scale of the Gen1 PUREVAP™ NSiR allows HPQ NANO technical provider PyroGenesis to take full advantage of a quick R&D feedback loop during the testing phase. Over short periods, tests are completed, material produced is analyzed by scanning electron microscope (SEM) imaging combined with X-ray diffraction (XRD), operational parameters are reviewed and system modifications and/or operational improvements are implemented. This is the key to our methodical approach of developing a truly disruptive low-cost technology that is going to change nano silicon materials manufacturing.

Tourillon added “HPQ’s Silicon R&D consortium has the depth and flexibility to meet the challenges as we strive to produce products for renewable energy storage participants and electric vehicle manufacturers, who are searching for cost-effective ways of increasing the Silicon contained in their batteries. Silicon’s potential to meet energy storage demand is undeniable, generating massive investments, and serious industry interest. We are very confident that the Silicon materials we are producing, with our expected low-cost scalable processes, will be in high demand by batteries, EV manufacturers and other participants in the ongoing renewable energy revolution.”

About PyroGenesis Canada Inc.

PyroGenesis Canada Inc., a high-tech company, is a leader in the design, development, manufacture and commercialization of advanced plasma processes and products. The Company provides its engineering and manufacturing expertise and its turnkey process equipment packages to customers in the defense, metallurgical, mining, advanced materials (including 3D printing), and environmental industries. With a team of experienced engineers, scientists and technicians working out of its Montreal office and its 3,800 m2 manufacturing facility, PyroGenesis maintains its competitive advantage by remaining at the forefront of technology development and commercialization. The Company’s core competencies allow PyroGenesis to provide innovative plasma torches, plasma waste processes, high-temperature metallurgical processes, and engineering services to the global marketplace. PyroGenesis’ operations are ISO 9001:2015 and AS9100D certified.

About HPQ Silicon

HPQ Silicon Resources Inc. (TSX-V: HPQ) is a Canadian Innovative Silicon Solutions Provider.

Silicon (Si), also known as silicon metal, is one of today’s key strategic materials needed for the decarbonization of the economy and the Renewable Energy Revolution (“RER”). Silicon is the most abundant element in earth’s crust but does not exist in its pure state and must be extracted from quartz (SiO2) in what has historically been a capital and energy-intensive process. HPQ is building a portfolio of silicon-based products using innovative scalable processes. The target objective is to produce high-value specialty Silicon products using technologies that will reduce energy consumption, GHG’s, and carbon footprint.

Working with PyroGenesis Canada Inc. (TSX-V: PYR), a high-tech company that designs, develops, manufactures and commercializes plasma-based processes, HPQ is developing:

a. The PUREVAP™ “Quartz Reduction Reactors” (QRR), an innovative process (patent pending), which will permit the one-step transformation of quartz (SiO2) into high purity silicon (Si) at reduced costs, energy input, and carbon footprint that will propagate its considerable renewable energy potential;

- HPQ believes it will become the lowest cost (Capex and Opex) producer of silicon (Si) and high purity silicon metal (3N – 4N Si);

b. Through its 100% owned subsidiary HPQ NANO Silicon Powders Inc, the PUREVAP™ Nano Silicon Reactor (NSiR), a new proprietary process that can use different purities of silicon (Si) as feedstock, to make spherical silicon nanopowders and nanowires;

- HPQ believes it can also become the lowest cost manufacturer of spherical Si nanopowders and silicon-based composites needed by manufacturers of next-generation lithium-ion batteries;

- During the coming months, spherical Si nanopowders and nanowires silicon-based composite samples requested by industry participants and research institutions’ will be produced using PUREVAP™ SiNR.

HPQ is also working with industry leader Apollon Solar of France to:

Use their patented process and develop a capability to produce commercially porous silicon (Si) wafers and porous silicon (Si) powders;

- The collaboration will allow HPQ to become the lowest-cost producer of porous silicon wafers for all-solid-state batteries and porous silicon powders for Li-ion batteries;

- Develop the hydrogen generation potential of Silicon nanopowders for usage with the Gennao™ system;

- Commercialize, exclusively in Canada, and non-exclusive in the U.S.A., the Gennao™ H2 system, and the chemical powders required for the hydrolysis production of Hydrogen (“H2”).