Author: Dexter Johnson, The Graphene Council Editor

“Over the last decade-and-a-half of graphene’s development and commercialization, we have been regularly reminded of the costs and complexity of working with graphene, especially in comparison to established materials, like silicon.”

“But imagine a form of graphene that is high quality, low cost and repeatable in quality. The truth is you don’t have to imagine it. It exists and it’s called 3D graphene foam. It can be applied to just about any surface in seconds and looks poised to disrupt a number of application areas in the near future.”

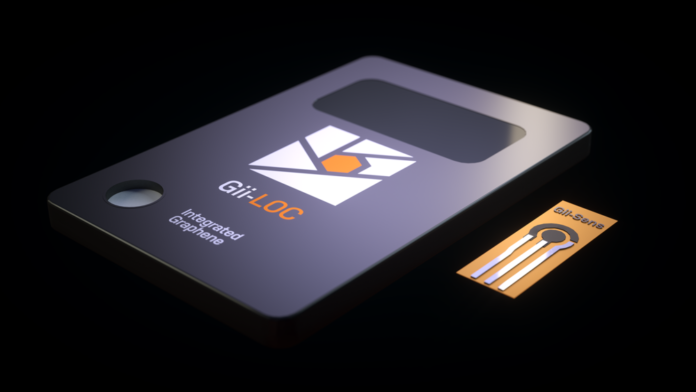

“Integrated Graphene Ltd., Stirling, Scotland, is now marketing a 3D foam graphene under the name “Gii” and is targeting biosensor and energy storage markets in its initial rollout.”

“Integrated Graphene recently joined The Graphene Council as a corporate member and we took that opportunity to speak to Alastair Carrington, Integrated Graphene’s chief commercial officer to learn more about 3D graphene foam and how we can expect to impact commercial markets in the coming years. Here is that interview.”

Q: How did you come to be a company marketing 3D graphene foam? Is it a technology that was spun out of research, or did you license the technology? What is the genesis of your company?

A: We have a strong history in medical diagnostics and we have always closely followed the progress of graphene. Integrated Graphene is founded by Claus Marquordt, CEO, and Marco Caffio, CSO. Claus is an expert is design for manufacture engineering with 20 years’ experience within the world’s leading diagnostic companies and Marco is a physical chemist specialising in 2D materials whose research has been split across industry and academia. Together they saw graphene was never held back due to the materials potential performance, but much more the cost, scale and reproducibility issues of the material.

Together Claus and Marco invented and initially self-funded through diagnostic service revenues, a unique design for manufacture technique for producing pure 3D Graphene Foam at ambient temperature, on any substrate, in seconds. The outcome is graphene that is accessible to industry and enables step change in performance within their desired applications.

Q: What is 3D graphene foam? What are its constituent parts? How is it made? Can it be produced with any kind of graphene (graphene oxide, graphene nanoplatelets, CVD graphene)? If it can be made with different kinds of graphene, how does each type of graphene change its properties and applications?

A: Our pure 3D Graphene Foam, Gii, is a complex of single layer and double layer graphene that is randomly assorted to form a permanent sponge-like structure. This provides an extremely large electrochemically active surface area that increases the performance of graphene within a defined space. We are able to process our Gii further to enhance it for specific applications such as energy storage and sensing.

For energy storage and sensing applications this means we are able to provide more active surface area for ions and molecules to be absorbed/ detected enabling a step change in performance for both.

Q. How is 3D graphene foam distributed to clients? In other words, you are marketing it for energy storage and biosensors. Are you supplying your graphene 3D foam to battery and sensor manufacturers or are you making sensors and batteries yourself?

A: We are an advanced material supplier across market verticals, to enable product innovators to access future technology performance, today. We work directly with disruptive manufacturers both within energy storage and sensing. We supply them with enhanced graphene foam, Gii, on plastic film, which they incorporate into a product.

We are able to support our sensing manufacturing partners due to our legacy diagnostic development business. We can provide full assay / platform development for biosensors / LOC / point-of-care tests from concept to commercialization. This range of services covers all biosensor development aspects, from sample in to reading out.

Q: Can you talk about some of your clients and how they are using your 3D graphene foam and the process by which they have adopted the material, i.e. did you have difficulty in getting them to adopt the material?

A: The first market we have launched into is biosensing. Our first product Gii-Sens, a pure 3D graphene sensing electrode, has been designed to directly replace the existing competing transducing electrode materials such as carbon, gold, “graphene” electrodes. We have made sure that our electrodes are universally applicable to what existing researchers use and competitively priced, as such we have a low barrier to adoption.

The main difficulty is many researchers have already been burnt by the promise of graphene, so initial barriers tend to be high until they see our data.

Q: What are the future applications for the 3D graphene foam beyond the initial applications you have identified? What areas do you expect this material could potentially find application?

A: We can tailor Gii to fulfill the vast majority of market demands for graphene. Currently we are focused on enhanced electro-chemical systems and our two entry markets of Biosensing and Energy Storage (supercapacitors). We intend to access a plethora of market verticals, the key deciding factor for entry will always be the market demand and our capability to tailor solutions to that market.