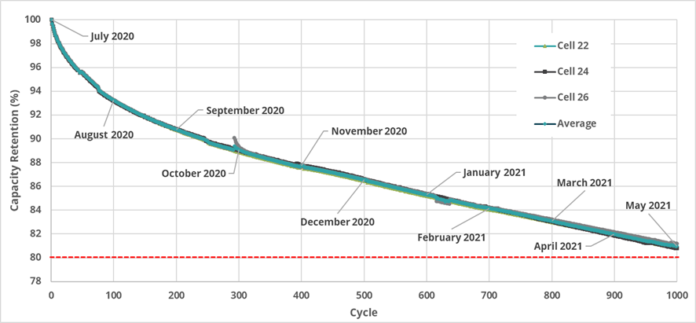

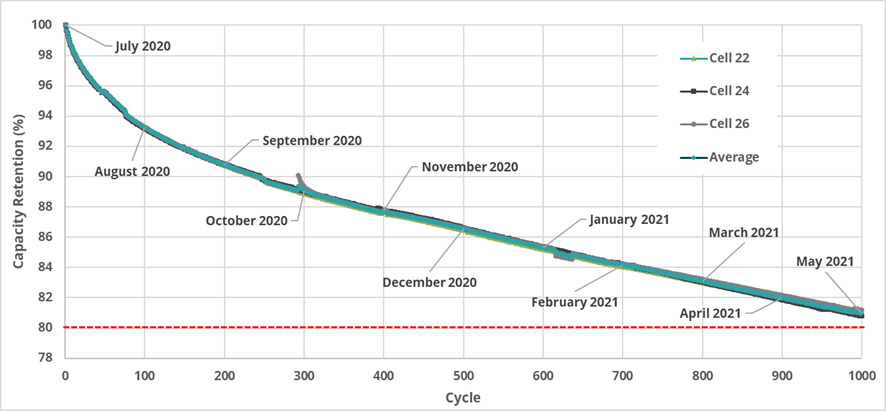

Mason Graphite Inc., Montreal, Quebec, Canada, (TSX.V: LLG; OTCQX: MGPHF) has announced that the cycling tests, carried out on its full prototype pouch cell batteries, are conclusive, having crossed the objective of 1,000 charge & discharge cycles while maintaining a capacity retention of 80.6%. This performance unequivocally ranks the Lac Guéret graphite among one of the best performing Li-ion anode materials presently available commercially in all applications, including electric vehicles.

This value-added transformation process was developed in collaboration with the National Research Council of Canada (“NRC”) and Corem, a research and innovation center in Quebec City. The process was designed based on a thorough benchmarking study completed from the onset of this battery material program, ensuring that the resulting product would meet the general requirements and specifications of battery manufacturers.

This achievement enhances the Company’s ability to execute on the commercialisation of the Lac Gueret graphite as a key component in the rapidly expanding battery market.

Commercialisation

The Company has expanded its workforce in order to expedite the commercialisation activities, which are expected to progress rapidly in the months ahead. The team at Mason Graphite possesses significant experience in commercialisation having led the commercialisation efforts and built the client base of a well recognized global graphite producer. This includes having qualified and distributed graphite products in all applications, including to most globally recognized alkaline and Li-ion battery manufacturers.

Battery Material Program

Mason Graphite has been working since 2015 on the development and improvement of its transformation process with the NRC. Mason Graphite and its partners have developed and mastered the purification, shaping and ultimately coating processes to meet the chemical and physical properties required to achieve the electrochemical performance sought by battery manufacturers.

The NRC is Canada’s largest federal research and development organization and partners with Canadian industry to take research impacts from the lab to the marketplace. The NRC offers a variety of scientific, engineering, and technical services, including expertise and facilities for clean and energy efficient transportation technologies. The NRC’s Automotive and Surface Transportation Research Centre battery prototyping line is equipped to produce, prototype, and test raw materials from the mine through to fabrication. The collaboration between Mason Graphite and the NRC has resulted in a commercially viable conversion process for battery-grade graphite.

For the project team, achieving these results represents a significant step forward for the Canadian electric vehicle industry, but also for other potential lithium-ion battery applications.

The Coated Purified Spherical Graphite (“CSPG”) has been produced from a graphite concentrate from the Lac Guéret project deposit and has been replicated on a pilot scale with the involvement of Corem.

Francis Fournier, Corem’s President and CEO added: “We are proud of our contribution since 2014 with Mason Graphite to the development of innovations for the extraction, purification and value-addition of the Lac Guéret project graphite. The tested coated spherical graphite was produced on a pilot scale at Corem’s facilities. The processes developed in collaboration with Mason Graphite are a good example of Corem’s role as a partner of the mining sector in the transition to a green economy such as the electrification of transportation.”

Jean L’Heureux, Chief Operating Officer of Mason Graphite, concluded: “The accomplishment celebrated today is the result of thousands of hours of work carried out by the Mason Graphite’s team and by our partners. We would like to thank everyone involved for their invaluable contribution to this achievement”.

The latest results of the three test cells are presented in the graph below:

Methodology

The batteries are tested at a rate of C/3, meaning 3 hours to charge and 3 hours to discharge, hence completing about 4 full cycles per day. The cathode used is of the NMC532 type. Capacity retention is calculated on the discharge capacity with respect to the first cycle.

CSPG Pilot Campaign

A new CSPG pilot plant production run is currently taking place at Corem and at Mason Graphite’s own facility in Quebec City. The CSPG thus produced will be used to provide further samples for testing by potential customers during the commercialisation campaign.

Developing the Next Generation of Anode Materials

Spherical graphite enhanced with silicon (“Si”) metal is a growing trend in Li-ion anode materials as Si additions result in higher overall energy densities in batteries. To date, the main drawback has been the difficulty to control the swelling of the Si during charging time, which leads to mechanical challenges.

Mason Graphite has been working for several months with a strategic partner specializing in innovative solutions for the development of a next generation high energy density Si-enhanced anode material. The partnership aims to engineer optimal anode materials integrating sufficient levels of Si, significantly increasing the capacity of lithium-ion batteries, whilst limiting the concentrations in order to curb any swelling to a manageable level. This approach aims at ensuring that these innovative products can be easily integrated into existing applications and battery manufacturing equipment, infrastructure, and supply chain.

The preliminary tests of Lac Guéret spherical graphite enhanced with Si have demonstrated exceptional electrochemical performance. Additional tests are underway, and the Company will communicate more details as the program progresses.

Stock Option Plan Amendments

The Company also announces that the Board approved a series of amendments to the stock option plan of the Company, as amended and restated (the “Option Plan”), to, among other things (i) increase the number of options grantable under the Option Plan from 11,000,000 to 13,500,000, (ii) clarify (a) the reasons for which an option may be automatically terminated or cancelled, (b) the events for which an option (or the ability to exercise such option) may be assigned or transferred, and (c) the events for which the Board may accelerate the vesting of options or terminate or cancel options, and (iii) make a series of “house-keeping” amendments. A summary description of the Option Plan, as amended, will be included in the management information circular for the next annual general meeting of shareholders of the Company. No options are being granted to directors or officers at this time.

About Mason Graphite

Mason Graphite is a Canadian corporation dedicated to the production and transformation of natural graphite. Its strategy includes the development of value-added products, notably for green technologies like transport electrification. The Company also owns 100% of the rights to the Lac Guéret graphite deposit, one of the richest in the world. The Company is managed by an experienced team cumulating many decades of experience in graphite, covering production, sales, as well as research and development.